Oct 4, 2016

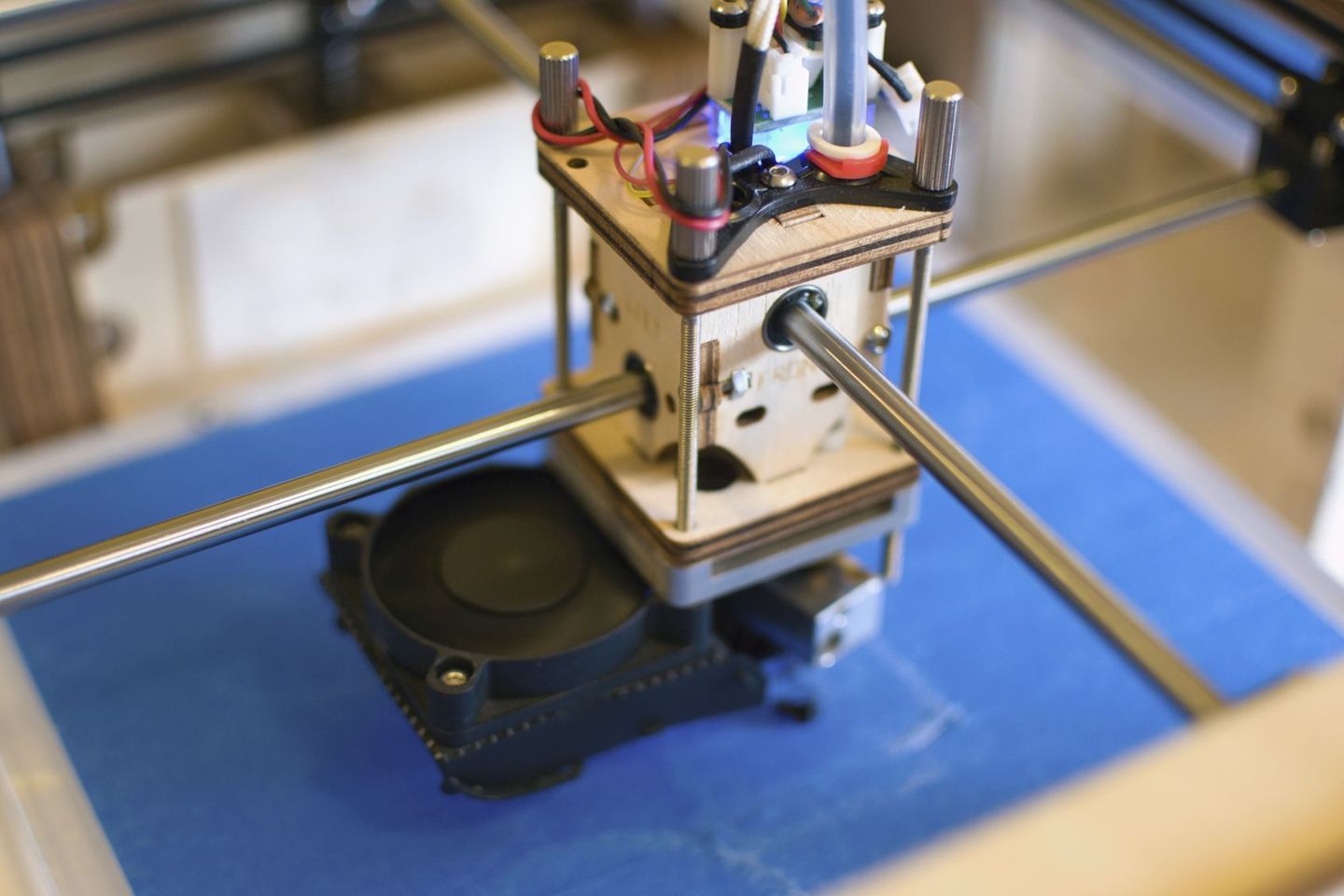

Doctors Can Now 3D-Print Bones On Demand, Thanks to a New “Hyperelastic” Material

Posted by Shailesh Prasad in categories: 3D printing, biotech/medical

In Brief.

- New 3D printed bones are ‘hyperelastic,’ making them more malleable during procedures.

- 3D printers in hospitals could provide the hyperelastic bone ink, so surgeons could make implants in 24 hours.

Remarkable.

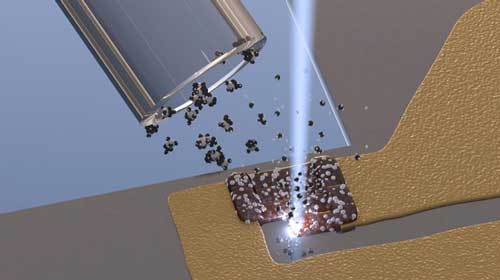

This best describes the new bone-mending technology developed at Northwestern University in Evanston, Illinois by Ramille Shah and her colleagues. They used ink made from a natural bone mineral called hydroxyapatite, mixed with PLGA, a mineral-binding polymer that makes the implants elastic.