3D print materials and products with superconducting properties is truly a breakthrough towards the mass production of various complex materials. I see this as a large step forward for 3D and placing things on an evolution track to even mass produce synthetic diamonds.

3D printing is revolutionizing many areas of manufacturing and science. In particular, 3D printing of metals has found novel applications in fields as diverse as customized medical implants, jet engine bearings and rapid prototyping for the automotive industry.

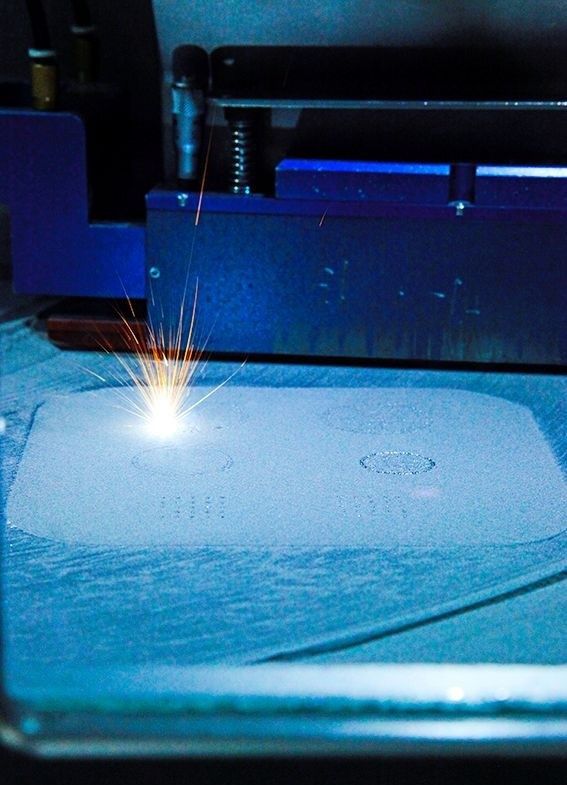

While many techniques can be used for 3D printing with metals, most rely on computer-controlled melting or sintering of a metal alloy powder by a laser or electron beam. The mechanical properties of parts produced by this method have been well studied, but not enough attention has focused on their electrical properties.

Now in a paper appearing this week on the cover of the journal Applied Physics Letters, a team of University of Melbourne and University of Western Australia researchers report creating a resonant microwave cavity that they 3D printed viaan aluminum-silicon alloy (Al-12Si). It exhibits superconductivity when cooled below the critical temperature of aluminum (1.2 Kelvin).

Comments are closed.