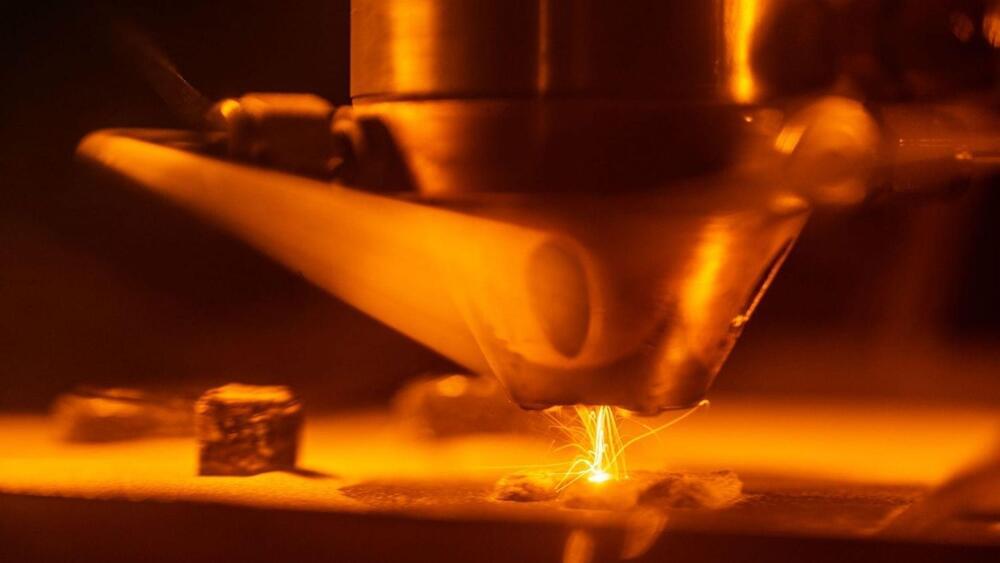

Researchers have come up with a new way to use 3D printing to make a new superalloy.

A group of researchers has developed a new superalloy resistant to high temperatures. This could if ever brought into production, prove revolutionary for the future of turbines.

This would increase its efficiency and decrease waste heat.

Craig Fritz/Sandia Labs.

At present, steam turbine blades, bearings, and seals are made of metal that tends to soften and elongate well before its melting point, which is one issue restricting the output of today’s power plants. If these issues are resolved, it is possible to increase the temperature of anything that uses a steam turbine to convert heat into electricity.

Comments are closed.