Jul 26, 2016

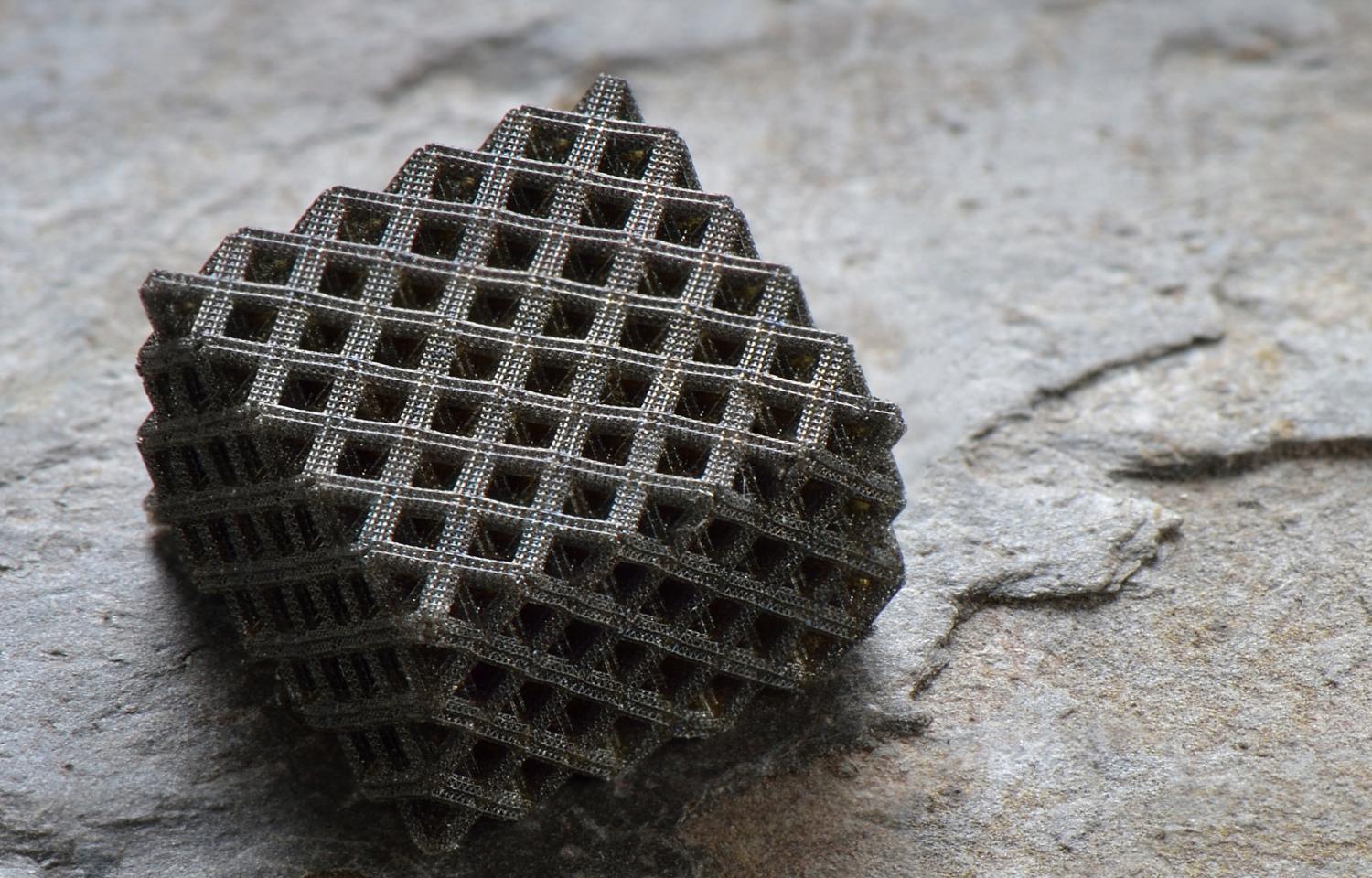

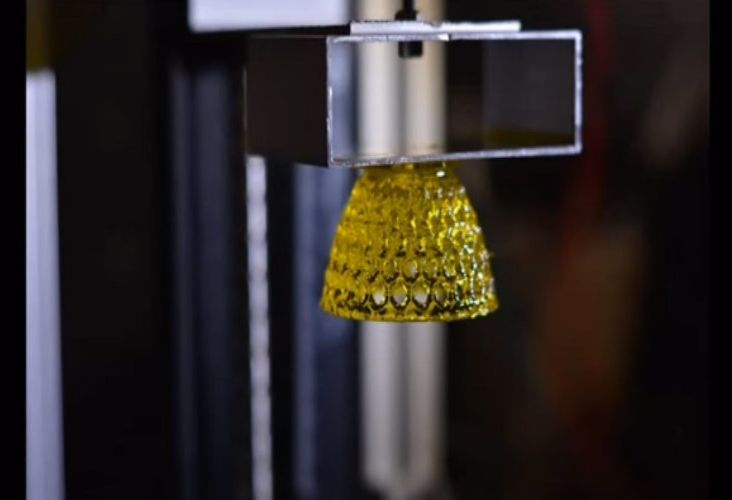

A bioink

Posted by Karen Hurst in categories: 3D printing, 4D printing, biotech/medical

Future Science Group (FSG) today announced the publication of a new article in Future Science OA looking to identify and define key terms associated with bioinks and bioprinting.

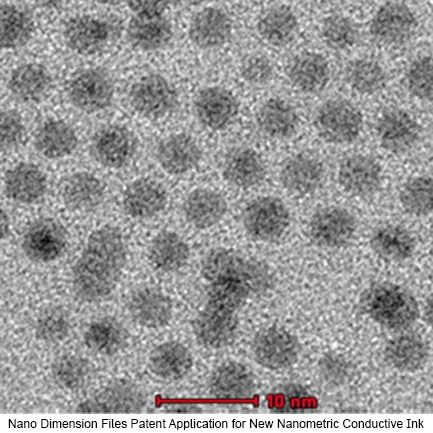

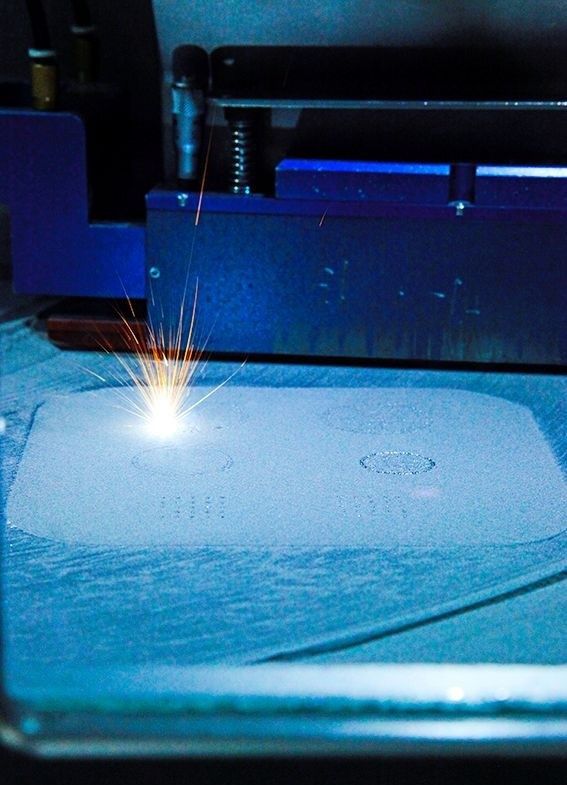

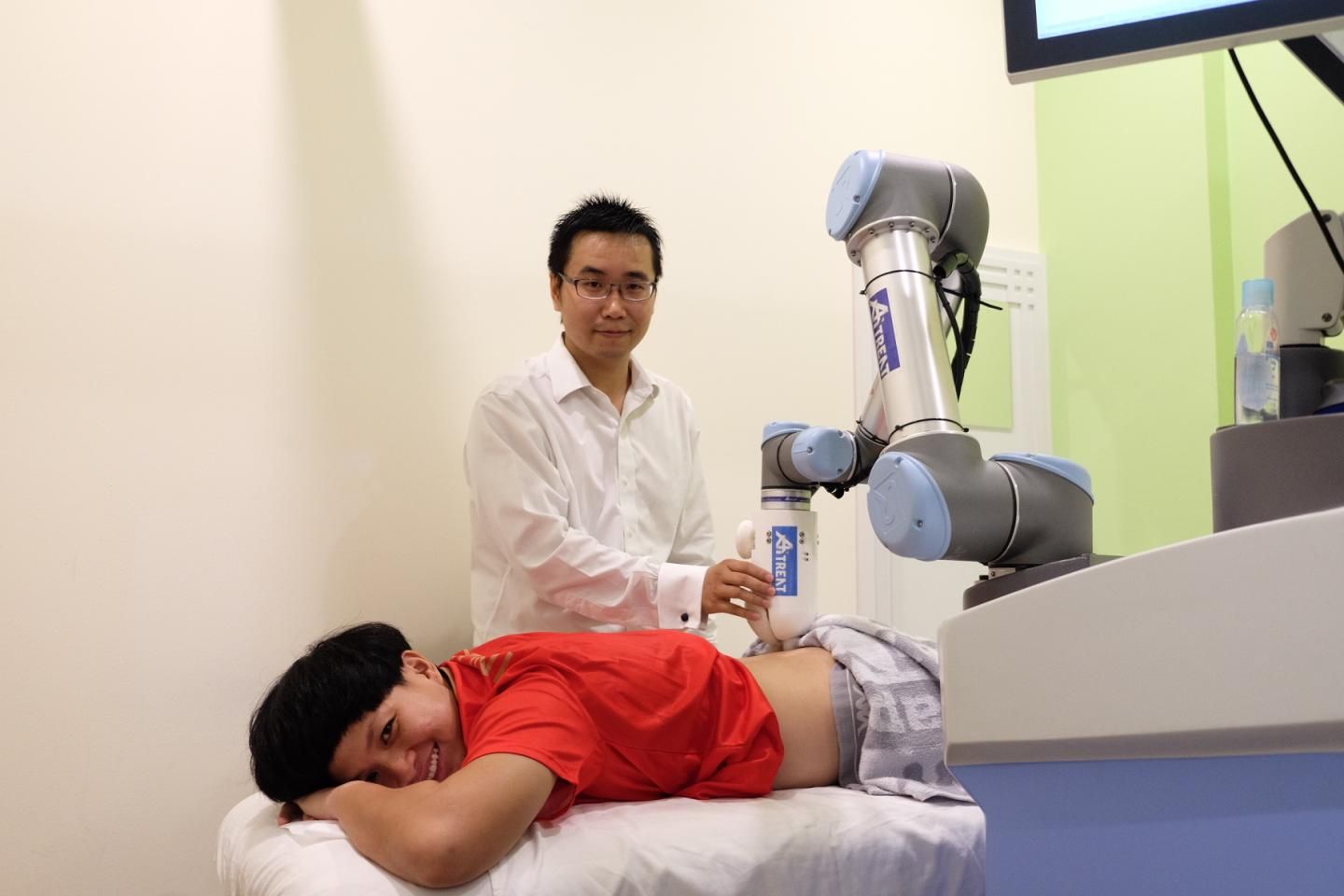

The use of 3D printing technologies for medical applications is a relatively new and rapidly expanding field, and is being approached in a multi-disciplinary manner. This has led to overlapping and ambiguous definitions within the field as a whole, and confusion over some terms, for example the prefix of ‘bio-‘. This new piece from William Whitford (GE Healthcare Life Sciences, USA) and James B. Hoying (Advanced Solutions Life Sciences, USA) introduces common definitions for 3D bioprinting-related terms, putting them into context. Terms defined within the article include 3D and 4D printing, bioadditive manufacturing, biofabrication, biomanufacturing, bioprinting, biomimetic printing and bioinks, among others.

“Additive manufacturing has transformed our approach to production in many ways,” notes Whitford. “There is now rapid development in the bioresearch, diagnostic and therapeutic applications for 3D printing. It’s difficult to even keep abreast of the number and types of relevant printing technologies, applications and vocabulary. We here identify some of the terms recently coined in this arena.”