Jan 23, 2020

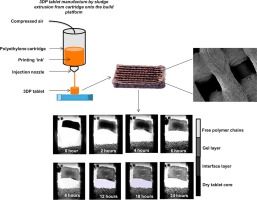

How 3D Printing, Vertical Farming, and Materials Science Are Overhauling Food

Posted by Omuterema Akhahenda in categories: 3D printing, food, robotics/AI, science

Within the next 10 years, what we eat and how it’s grown will be fundamentally transformed.

And converging exponential technologies—from materials science to AI-driven digital agriculture—are not slowing down. Today’s breakthroughs will soon allow our planet to boost its food production by nearly 70 percent, using a fraction of the real estate and resources, to feed 9 billion by mid-century.

What you consume, how it was grown, and how it will end up in your stomach will all ride the wave of converging exponentials, revolutionizing the most basic of human needs.

Continue reading “How 3D Printing, Vertical Farming, and Materials Science Are Overhauling Food” »