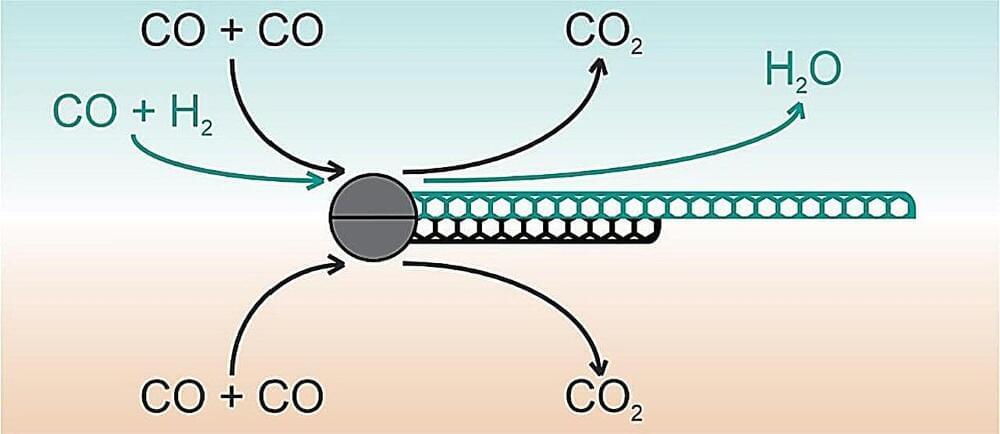

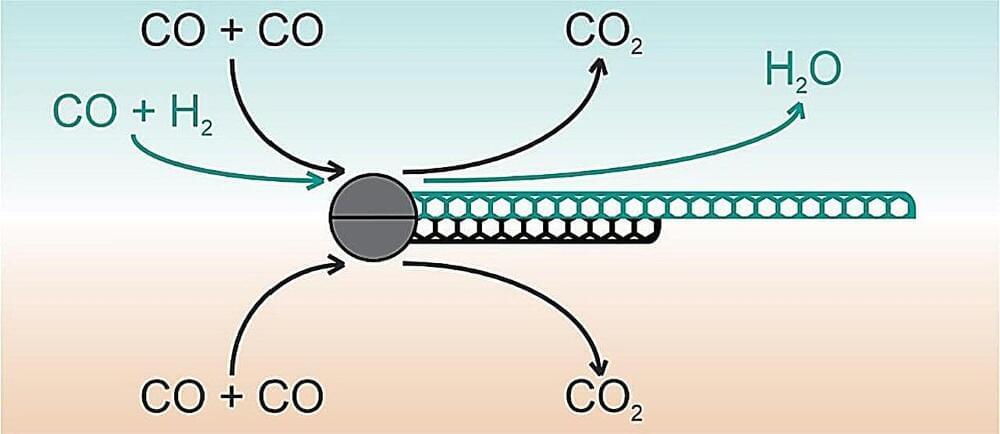

Skoltech scientists have found a way to improve the most widely used technology for producing single-walled carbon nanotube films—a promising material for solar cells, LEDs, flexible and transparent electronics, smart textiles, medical imaging, toxic gas detectors, filtration systems, and more. By adding hydrogen gas along with carbon monoxide to the reaction chamber, the team managed to almost triple carbon nanotube yield compared with when other growth promoters are used, without compromising quality.

Until now, low yield has been the bottleneck limiting the potential of that manufacturing technology, otherwise known for high product quality. The study has been published in the Chemical Engineering Journal.

Although that is not how they’re really made, conceptually, nanotubes are a form of carbon where sheets of atoms in a honeycomb arrangement—known as graphene—are seamlessly rolled into hollow cylinders.