Archive for the ‘3D printing’ category: Page 46

May 29, 2020

Researchers take a cue from nature to create bulletproof coatings

Posted by Quinn Sena in category: 3D printing

Shrimp, lobsters and mushrooms may not seem like great tools for the battlefield, but three engineers from the University of Houston are using chitin—a derivative of glucose found in the cellular walls of arthropods and fungi—and 3D printing techniques to produce high-impact multilayered coatings that can protect soldiers against bullets, lasers, toxic gas and other dangers.

May 26, 2020

New material could be used to make a liquid metal robot

Posted by Kelvin Dafiaghor in categories: 3D printing, engineering, nuclear energy, robotics/AI

Eric Klien

A liquid metal lattice that can be crushed but returns to its original shape on heating has been developed by Pu Zhang and colleagues at Binghamton University in the US. The material is held together by a silicone shell and could find myriad uses including soft robotics, foldable antennas and aerospace engineering. Indeed, the research could even lead to the creation of a liquid metal robot evoking the T-1000 character in the film Terminator 2.

The team created the liquid metal lattice using a special mixture of bismuth, indium and tin known as Field’s alloy. This alloy has the relatively unusual property of melting at just 62 °C, which means it can be liquefied with just hot water. Field’s alloy already has several applications – including as a liquid-metal coolant for advanced nuclear reactors.

Continue reading “New material could be used to make a liquid metal robot” »

May 23, 2020

Nano Comes to Life: How Nanotechnology Is Transforming Medicine and the Future of Biology

Posted by Mike Diverde in categories: 3D printing, biotech/medical, life extension, nanotechnology, neuroscience, quantum physics

If you’re interested in superlongevity and superintelligence, then I have a book to recommend., by Sonia Contera, is a book about the intersection of biotech and nanotech. Interesting and well written for the layman, the book covers some of the latest developments in nanotechnology as it applies to biological matters. Although there are many topics, I was primarily interested in the DNA nanobots, DNA origami, and the protein nanotechnology sections. My interest is piqued in these arenas due to my expectation that DNA nanobots and protein nanobots, as well as complex self-assembled custom nanostructures, are going to be key to some of the longevity technologies and some of the possible substrates for mind uploading that are key to superlongevity and superintelligence. There are also sections in the book on 3D bioprinted organs — progress and possibilities, as well as difficulties.

There is even a section that clearly was written specifically to address a discussion that has engaged my friends, Dinorah Delfin and Dan Faggella. The title is:

FUTURE DEVICES: QUANTUM PHYSICS MEETS BIOLOGY MEETS NANOTECHNOLOGY

Now, some might be tempted to consider that particular combination to be “woo woo”, however, please keep in mind the author’s credentials. Sonia Contera is a professor of biological physics in the Department of Physics at the University of Oxford.

May 23, 2020

Cellular Aquaculture — Feed The World and Save the Oceans — Lou Cooperhouse, President & CEO, BlueNalu — ideaXme — Ira Pastor

Posted by Ira S. Pastor in categories: 3D printing, bioengineering, biological, bioprinting, business, food, futurism, health, lifeboat, science

May 19, 2020

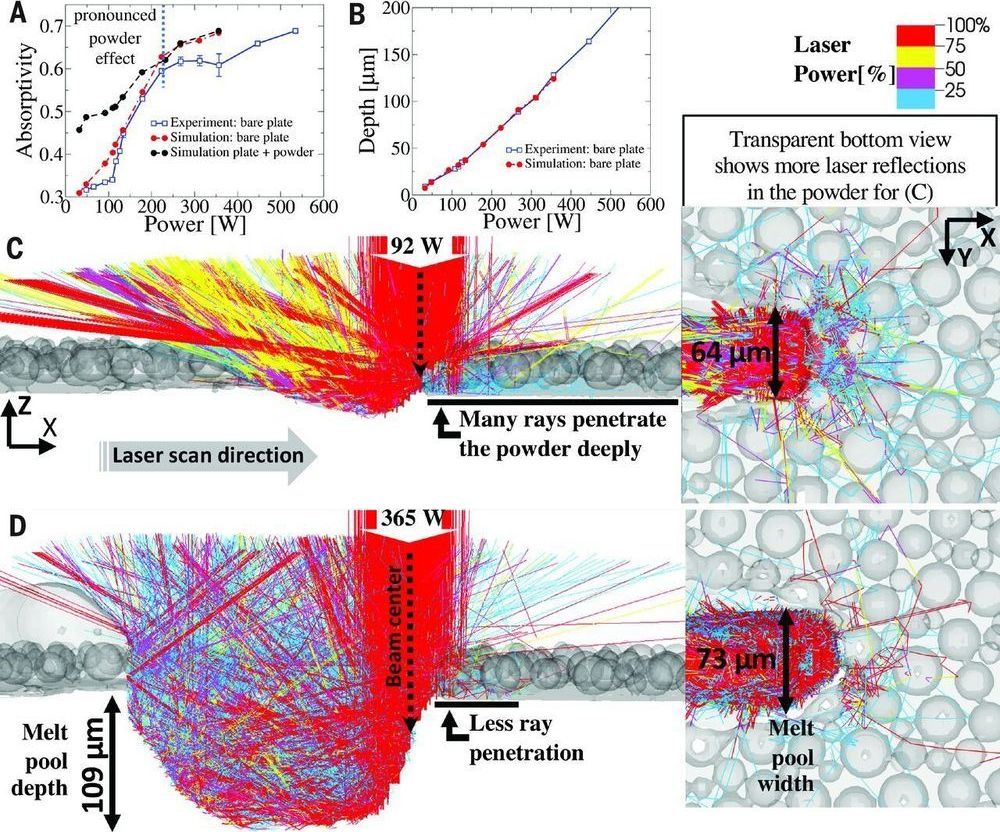

Controlling spatter during laser powder bed fusion found to reduce defects in metal-based 3D printing

Posted by Saúl Morales Rodriguéz in categories: 3D printing, biotech/medical

A team of researchers with members from Lawrence Livermore National Laboratory, Wright-Patterson Air Force Base and the Barnes Group Advisors found that controlling spatter during laser-powder bed fusion can reduce defects in metal-based 3D printing. In their paper published in the journal Science, the group describes studying the additive manufacturing printing methodology and what they learned about it. Andrew Polonsky and Tresa Pollock with the University of California, Santa Barbara have published a Perspective piece on the work done by the team in the same journal issue.

As additive manufacturing printing methodologies mature, new materials are being tested to find out if they might be used in 3D printers to create new products. In recent years, this has extended to metals. One such technique is called laser-powder bed fusion (L-PBF). It involves the use of a high-powered laser to melt and fuse metallic powders layer by layer to produce a 3D part. It has been hoped that the technique could eventually be used for aerospace and biomedical applications. But thus far, such efforts have fallen short due to the large number of defects that occur with the process. In this new effort, the researchers have discovered a way to reduce such defects, perhaps paving the way for the technique to finally fulfill its promise.

To better understand why the L-PBF process leads to so many defects (such as undesired pores) the researchers conducted X-ray synchrotron experiments and built predictive multi-physics models to gain a better understanding of what occurs during printing. One of their goals was to better understand how energy is absorbed during printing with powder layers that are only a few particles thick.

May 18, 2020

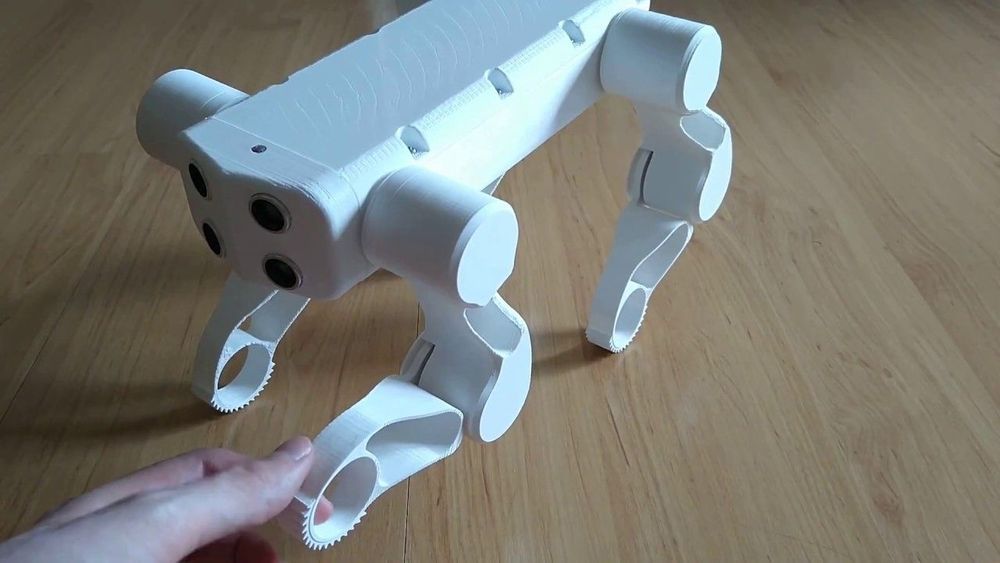

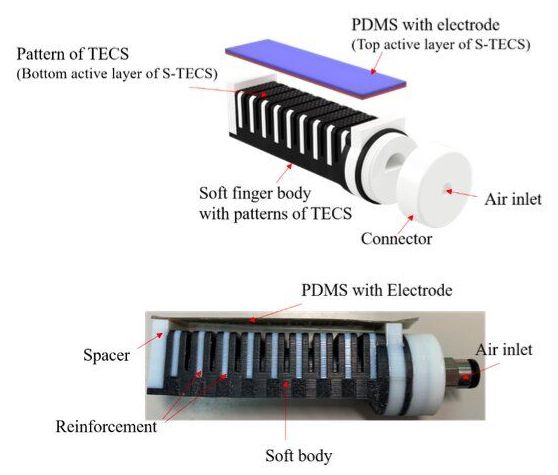

A soft robotic finger fabricated using multi-material 3D printing

Posted by Saúl Morales Rodriguéz in categories: 3D printing, robotics/AI

Researchers at Zhejiang University of Technology, Tianjin University, Nanjing Institute of Technology and Ritsumeikan University have recently created a soft robotic finger that integrates a self-powered curvature sensor using multi-material 3D printing technology. The new robotic finger, presented in a paper published in Elsevier’s Nano Energy journal, is made of several materials, including a stretchable electrode, polydimethylsiloxane (PDMS), AgilusBlack, VeroWhite and FLX9060.

“Soft robots have the potential to bridge the gap between machines and humans, but it is important for them to ensure a safe interaction between humans, objects and the environment,” Mengying Xie, co-author of the paper, told TechXplore. “Embedded soft sensors are critical for the development of controllable soft robots that can fulfill their full potential in practical applications.”

In their previous research, part of the research team working at Ritsumeikan University developed a fully multi-material 3D printed gripper with variable stiffness that could achieve robust grasping of objects. In this new study, Xie, Zhu and their colleagues drew inspiration from this previous work and set out to create a 3D-printed soft finger with sensing capabilities that could monitor its bending movements.

May 17, 2020

10 Coolest 3D Printed Cars

Posted by Quinn Sena in categories: 3D printing, transportation

Believe it or not, 3D printed cars are a reality.

Although you won’t be able to find 3D printed cars at your local car dealership just yet, there are some very interesting concepts out there that do a great job of presenting the possibilities of 3D printing in the automotive industry. They even represent the first steps towards mass-produced 3D printed cars.

Here are 10 of the coolest cars that are 3D printed or contain 3D printed parts. Just keep in mind that most of them aren’t available for purchase.

May 17, 2020

Czinger 21C: the world’s first 3D printed hypercar | Top Gear

Posted by Omuterema Akhahenda in categories: 3D printing, energy, military

The Czinger 21C is a 1,233bhp 3D printed hypercar complete with a turbo V8 revving to 11,000rpm, a 1+1 layout and $1.7m price tag. Oh, and the big news is it’s 3D printed. Well, large sections of the chassis are, paving the way for a revolutionary new car manufacturing process that could change… everything. It’s mind-blowing stuff, so let Jack Rix be your guide around California’s Koenigsegg rival.

WATCH MORE TOP GEAR:

http://bit.ly/TG-S27

http://bit.ly/StigCams

http://bit.ly/TG-Mercedes

Continue reading “Czinger 21C: the world’s first 3D printed hypercar | Top Gear” »

May 16, 2020

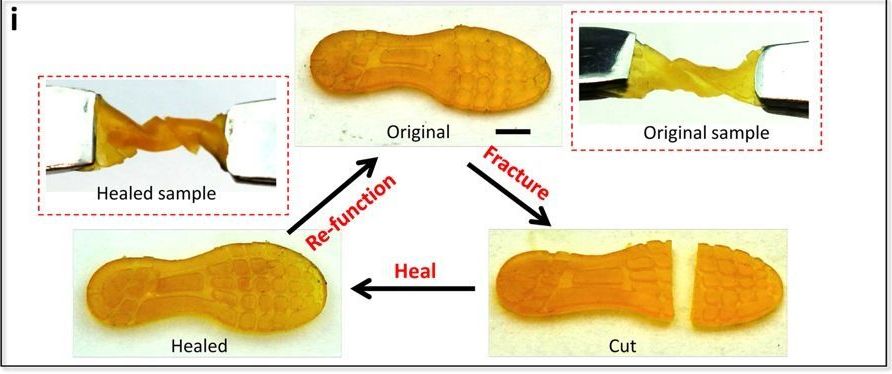

Self-repairing shoes may be a reality thanks to 3D-printed rubber

Posted by Quinn Sena in categories: 3D printing, robotics/AI

Circa 2019 face_with_colon_three

Shoes will invariably wear out with enough use, but scientists might have found a way to delay the shopping trip for their replacements. A USC team has created a self-healing 3D-printed rubber that could be ideal for footwear, tires and even soft robotics. The effort involves 3D printing the material with photopolymerization (solidifying a resin with light) while introducing an oxidizer at just the right ratio to add self-healing properties without slowing down the solidifying process.

Continue reading “Self-repairing shoes may be a reality thanks to 3D-printed rubber” »