The first logic gate to operate at femtosecond timescales could help usher in an era of information processing at petahertz frequencies – a million times faster than today’s gigahertz-scale computers. The new gate, developed by researchers at the University of Rochester in the US and the Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) in Germany, is an application of lightwave electronics – essentially, shuffling electrons around with light fields – and harnesses both real and virtual charge carriers.

In lightwave electronics, scientists use laser light to guide the motion of electrons in matter, then exploit this control to create electronic circuit elements. “Since light oscillates so fast (roughly a few hundred million times per second), using light could speed up electronics by a factor of roughly 10 000 as compared to computer chips,” says Tobias Boolakee, a laser physicist in Peter Hommelhoff’s group at the FAU and the first author of a study in Nature on the new gate. “With our present work, we have been able propose the idea for a first light field-driven logic gate (the fundamental building block for any computer architecture) and also demonstrate its working principle experimentally.”

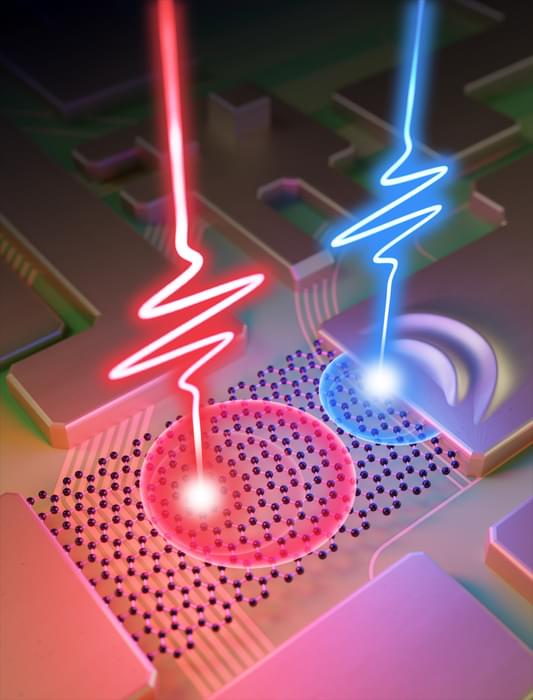

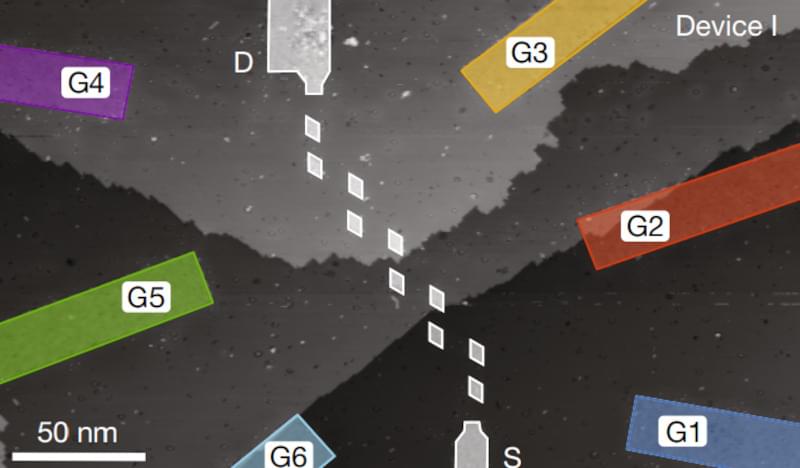

In the work, Boolakee and colleagues prepared tiny graphene-based wires connected to two gold electrodes and illuminated them with a laser pulse lasting a few tens of femtoseconds (10-15 s). This laser pulse excites, or sets in motion, the electrons in graphene and causes them to propagate in a particular direction – so generating a net electrical current.