Nov 29, 2022

Elon Musk picks up a fight with Apple- but why?

Posted by Gemechu Taye in categories: Elon Musk, mobile phones

The anti-Apple crowd has the backing of the world’s richest person.

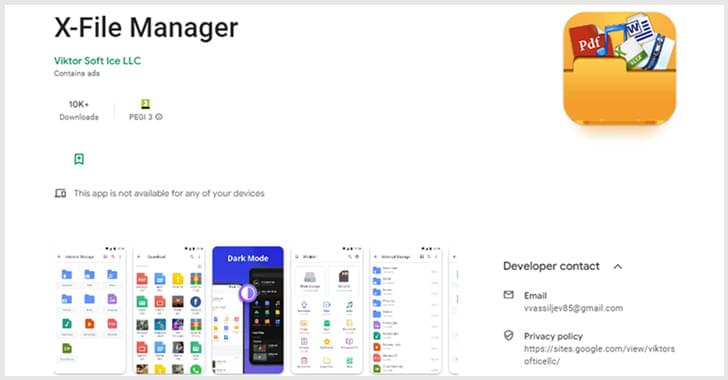

Elon Musk might have just propped himself as the new face of the anti-Apple group working to counter the iPhone maker’s monopoly in the app market. In a tweet, Musk accused Apple of threatening to withhold Twitter from the App Store without giving any specific reason and called it censorship.

Since his Twitter acquisition, Elon Musk has primarily been in the news for the things that have happened inside the social media company, whether it is firing half of the workforce or asking the remaining crew to commit more hours of work at a higher intensity to build a new version of the social media company.