Category: robotics/AI – Page 176

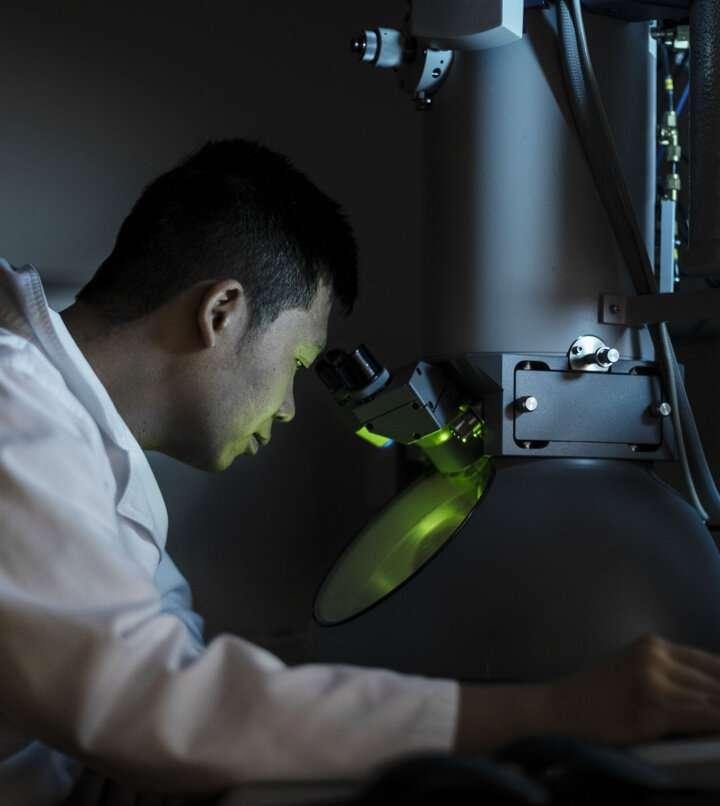

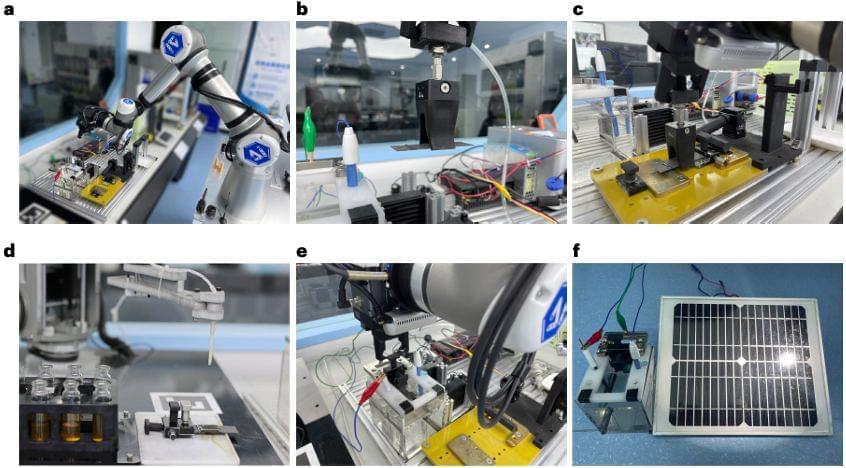

Breaking oxygen out of a water molecule is a relatively simple process, at least chemically. Even so, it does require components, one of the most important of which is a catalyst. Catalysts enable reactions and are linearly scalable, so if you want more reactions quickly, you need a bigger catalyst. In space exploration, bigger means heavier, which translates into more expensive. So, when humanity is looking for a catalyst to split water into oxygen and hydrogen on Mars, creating one from local Martian materials would be worthwhile. That is precisely what a team from Hefei, China, did by using what they called an “AI Chemist.”

Unfortunately, the name “AIChemist” didn’t stick, though that joke might vary depending on the font you read it in. Whatever its name, the team’s work was some serious science. It specifically applied machine learning algorithms that have become all the rage lately to selecting an effective catalyst for an “oxygen evolution reaction” by utilizing materials native to Mars.

To say it only chose the catalyst isn’t giving the system the full credit it’s due, though. It accomplished a series of steps, including developing a catalyst formula, pretreating the ore to create the catalyst, synthesizing it, and testing it once it was complete. The authors estimate that the automated process saved over 2,000 years of human labor by completing all of these tasks and point to the exceptional results of the testing to prove it.

Pathway has just raised a $10 million Seed round to build live AI systems that, claims the company, think and learn in real-time as humans do.

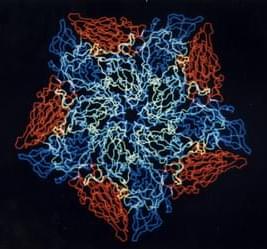

Researchers used machine learning to optimize the process by which a tiny cage is opened to release a molecule.

Researchers have designed a tiny structure that could help deliver drugs inside the body [1]. The theoretical and computational work required machine learning to optimize the parameters for the structure, which could stick to a closed shell containing a small molecule and cause the shell to open. The results demonstrate the potential for machine learning to assist in the development of artificial systems that can perform complex biomolecular processes.

Researchers are developing artificial molecular-scale structures that could perform functions such as drug delivery or gene editing. Creating such artificial systems, however, usually entails a frustrating tradeoff. If the components are simple enough to be computationally tractable, they are unlikely to yield complex interactions. But if the components are too complex, they become harder to combine and coordinate. Machine learning can reduce the computational cost of designing useful artificial systems, according to graduate student Ryan Krueger of Harvard University.

There are over 30,000 weather stations in the world, measuring temperature, precipitation and other indicators often on a daily basis. That’s a massive amount of data for climate researchers to compile and analyze to produce the monthly and annual global and regional temperatures (especially) that make the news.

Now researchers have unleashed artificial intelligence (AI) on these datasets to analyze temperature extremes in Europe, finding excellent agreement compared to existing results that used traditional methods, and as well have uncovered climate extremes not previously known. Their work has been published in Nature Communications.

With the world’s climate changing rapidly, it is important to know how temperature and precipitation extremes are changing, so planners can adapt to the extremes here now and to what’s coming.

Kuhn’s taxonomy of consciousness connects various theories to deep questions about human existence and AI, based on his extensive dialogue with over 200 experts.

“Out of meat, how do you get thought? That’s the grandest question,” said philosopher Patricia Churchland to Robert Lawrence Kuhn, the producer and host of the acclaimed PBS program Closer to Truth and member of FQxI’s scientific advisory council.

Kuhn has now published a comprehensive taxonomy of proposed solutions and theories regarding the hard problem of consciousness. His organizing framework aims to assess their impact on meaning, purpose, and value, as well as on AI consciousness, virtual immortality, survival beyond death, and free will. His work, titled ‘Landscape of Consciousness,’ appeared in the August 2024 issue of the journal Progress in Biophysics and Molecular Biology.

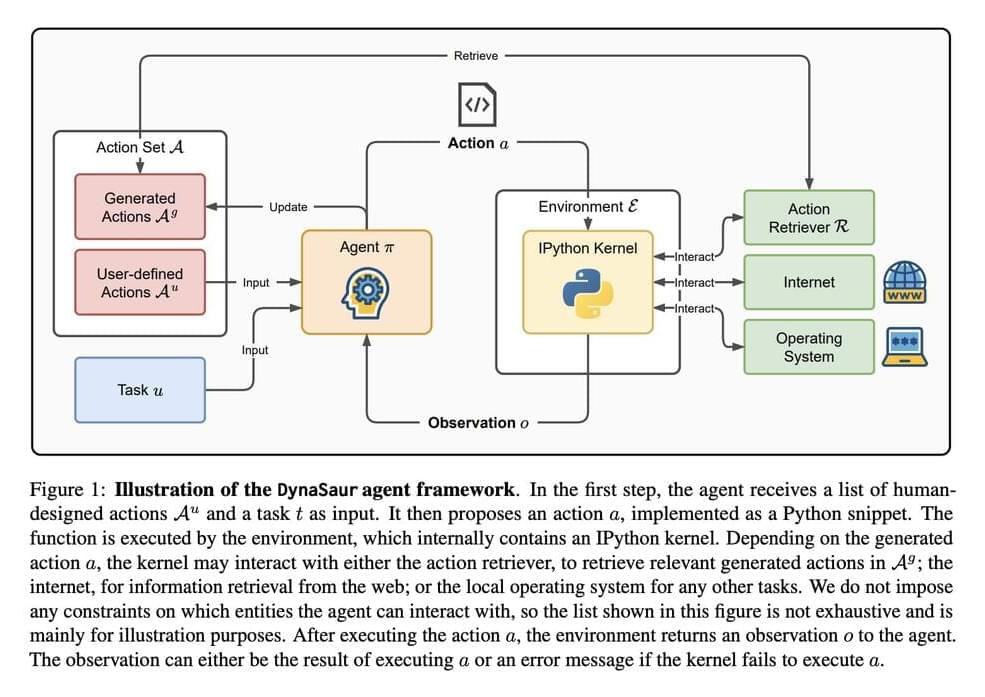

Traditional large language model (LLM) agent systems face significant challenges when deployed in real-world scenarios due to their limited flexibility and adaptability. Existing LLM agents typically select actions from a predefined set of possibilities at each decision point, a strategy that works well in closed environments with narrowly scoped tasks but falls short in more complex and dynamic settings. This static approach not only restricts the agent’s capabilities but also requires considerable human effort to anticipate and implement every potential action beforehand, which becomes impractical for complex or evolving environments. Consequently, these agents are unable to adapt effectively to new, unforeseen tasks or solve long-horizon problems, highlighting the need for more robust, self-evolving capabilities in LLM agents.

Researchers from the University of Maryland and Adobe introduce DynaSaur: an LLM agent framework that enables the dynamic creation and composition of actions online. Unlike traditional systems that rely on a fixed set of predefined actions, DynaSaur allows agents to generate, execute, and refine new Python functions in real-time whenever existing functions prove insufficient. The agent maintains a growing library of reusable functions, enhancing its ability to respond to diverse scenarios. This dynamic ability to create, execute, and store new tools makes AI agents more adaptable to real-world challenges.

The technical backbone of DynaSaur revolves around the use of Python functions as representations of actions. Each action is modeled as a Python snippet, which the agent generates, executes, and assesses in its environment. If existing functions do not suffice, the agent dynamically creates new ones and adds them to its library for future reuse. This system leverages Python’s generality and composability, allowing for a flexible approach to action representation. Furthermore, a retrieval mechanism allows the agent to fetch relevant actions from its accumulated library using embedding-based similarity search, addressing context length limitations and improving efficiency.

Combining quantum science with machine learning has led to a model that can accurately measure how surfaces feel to the touch.

Join us https://app.ploutos.dev/streams/gorgeous-horse.

#physics #AI #NobelPrize

Physics, AI, and the nobel prize.

Speakers: Cecile Tamura, Robert Pray DVMedia, Ivan Maksymov, Riju Pahwa