Archive for the ‘space travel’ category: Page 359

WOW!

This is the story of SpaceIL — the most amazing private Israeli space project — and the three founders behind it: Yariv Bash, Kfir Damari, and Yonatan Winetraub.

The landing might have not worked, but the spacecraft is ON THE MOON!

Artemis is the name of NASA’s program to return astronauts to the lunar surface by 2024. We are going forward to the Moon to stay.

Jun 4, 2019

This Short Film Is Written Entirely By AI

Posted by Marco Monfils in categories: robotics/AI, space travel

Viva Space Ship Day

For 10% off your first purchase, go to

http://www.squarespace.com/austinmcconnell

Continue reading “This Short Film Is Written Entirely By AI” »

Jun 3, 2019

Can The Science and Philosophy of Information Solve The Problem of Time?

Posted by Alex Vikoulov in categories: biotech/medical, entertainment, science, space travel

In our day and age when the science and philosophy of information start to eclipse traditional disciplines on all fronts, the importance of asking the right kinds of questions in light of a new rhetoric cannot be overestimated. Hereafter you can find three videos with their transcripts related to D-Theory of Time, or Digital Presentism, that I cover extensively in my new book The Syntellect Hypothesis: Five Paradigms of the Mind’s Evolution, as well as in my just-released ebook The Physics of Time: D-Theory of Time & Temporal Mechanics.

Will We Transcend The Temporal Dimension?: If you’re like me who loves thought-provoking sci-fi literature and movies, Interstellar and Arrival are both about transcending temporality, one through physics and the other through language. Arguably, these two outlooks on TIME reflect our current understanding as the most plausible ways to overcome the grips of impermanence.

If we look back at evolutionary emergence on our planet, the simplest organisms like primordial mitochondria, the front-runners at the onset of biological life, were able to perceive and move towards nutrients and away from environmental threats in an essentially one-dimensional existence.

Continue reading “Can The Science and Philosophy of Information Solve The Problem of Time?” »

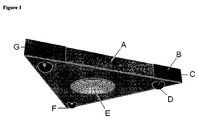

A spacecraft having a triangular hull with vertical electrostatic line charges on each corner that produce a horizontal electric field parallel to the sides of the hull. This field, interacting with a plane wave emitted by antennas on the side of the hull, generates a force per volume combining both lift and propulsion.

Jun 2, 2019

Elon Musk talks next-gen Tesla Roadster details: SpaceX package, annual output, and why it matters

Posted by Klaus Baldauf in categories: Elon Musk, space travel, sustainability

Elon Musk’s appearance at Tesla owner-enthusiast Ryan McCaffrey’s Ride the Lightning podcast revealed a number of new details about the electric car maker’s upcoming halo vehicle, the next-generation Roadster. While addressing the all-electric supercar, Musk discussed the vehicle’s estimated yearly production numbers, its purpose, and some details about its “SpaceX package.”

Ever the candid interviewee, Musk admitted that the next-generation Roadster is really more like a dessert to the Model S, 3, X, and Y’s main course, in the way that its existence will probably not provide much of an impact to Tesla’s overall mission of accelerating the world’s transition to sustainable energy. Nevertheless, the Roadster still has a lot of merits, in the way that it could establish the superiority of pure electric propulsion compared to the internal combustion engine, bar none.

Musk noted that the Roadster is intended to outperform the best “Ferraris, Lamborghinis, and McLarens” on every dimension, on every level, including the track, thereby erasing the halo effect of gas cars. “We’re going to do things with the new Roadster that are kind of unfair to other cars. (It’s) crushingly good relative to the next best gasoline sports car,” Musk said.

Jun 1, 2019

New way to protect against high-dose radiation damage discovered

Posted by Paul Battista in categories: biotech/medical, military, space travel

Damage of healthy intestinal cells is the main disadvantage of radiotherapy leading to the discontinuation and failure of an efficient cancer treatment, potentially causing a quick tumour recurrence. Now, a discovery published in Science by scientists from the Growth Factors, Nutrients and Cancer Group at the Spanish National Cancer Research Centre (CNIO) might be useful to protect healthy intestinal cells from radiation damage. The consequences of their findings in mice might radically change the way humans manage exposure to high levels of radiation; both for cancer research and treatment as well as for other areas like space explorations, nuclear warfare or nuclear accidents.

The Group’s work focuses on URI, a protein whose functions remain not yet fully understood. However, previous studies from the Group have found that abnormal levels of expression of this protein in certain organs can cause cancer. The study now published in Science shows that high levels of URI protein protect mice from radiation-induced intestinal damage, whereas low or no detectable levels of the protein can lead to gastrointestinal syndrome and death.

“The precise functions of URI have not been identified yet,” says Nabil Djouder, Head of the Growth Factors, Nutrients and Cancer Group at CNIO and leader of the study. “Just like pH or temperature, which the organism needs to maintain within a certain range, URI levels must also be kept within a very narrow window to regulate the proper functioning of other proteins. When URI levels are higher or lower than optimal, they may promote or protect against tumour development as well as other diseases, depending on the context.”

Continue reading “New way to protect against high-dose radiation damage discovered” »

May 31, 2019

Single Stage Point to Point Up To 6000 Miles With Mach 20 Starship

Posted by Quinn Sena in categories: Elon Musk, space travel

Elon Musk says adding two to four Raptor Engines to the Starship will let it go sub-orbital for 6000 miles at mach 20. This would mean trips like San Francisco to Shanghai or New York to Berlin. Many world cities are within 6000 miles of each other.

Boeing extended range 767s can reach 6000 miles and the newer 777 and 787 have longer ranges.

Continue reading “Single Stage Point to Point Up To 6000 Miles With Mach 20 Starship” »

May 30, 2019

In new space race, companies jostle for $1 trillion market

Posted by Klaus Baldauf in categories: Elon Musk, humor, internet, space travel

“We joke that ‘The Martian’ would have been a much more boring movie,” said Justin Kugler, a vice president at Made In Space.

Fifty years after the first men walked on the moon, a new space race is underway, this one for a piece of what Wall Street analysts say could become a $1 trillion global space market. Around the world, companies such as Made In Space are launching — often literally — new products and services, building satellites to provide broadband internet, spaceships to take tourists on zero-gravity rendezvous, and mining equipment to extract minerals from asteroids.

On HoustonChronicle.com: Elon Musk injects ‘X’ factor into space quest with bold vision, mixed track record.

Continue reading “In new space race, companies jostle for $1 trillion market” »