The future of technology has an age-old problem: rust. When iron-containing metal reacts with oxygen and moisture, the resulting corrosion greatly impedes the longevity and use of parts in the automotive industry. While it’s not called “rust” in the semiconductor industry, oxidation is especially problematic in two-dimensional (2D) semiconductor materials, which control the flow of electricity in electronic devices, because any corrosion can render the atomic-thin material useless. Now, a team of academic and enterprise researchers has developed a synthesis process to produce a “rust-resistant” coating with additional properties ideal for creating faster, more durable electronics.

The team, co-led by researchers at Penn State, published their work in Nature Communications (“Tailoring amorphous boron nitride for high-performance two-dimensional electronics”).

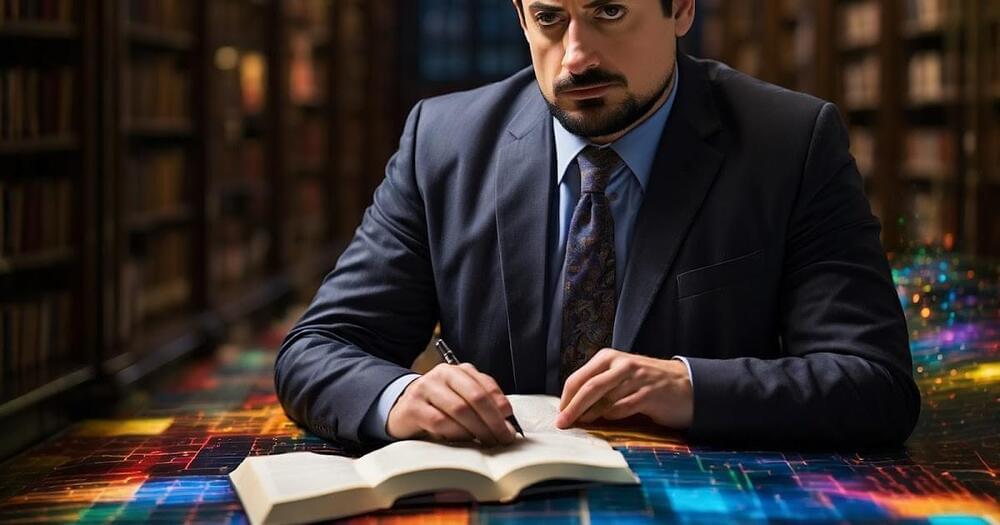

These materials are made from molybdenum disulfide, a two-dimensional semiconductor, grown on a sapphire surface. The triangular shapes seen are aligned because of a special process called epitaxy, where the material follows the pattern of the surface it’s grown on. Insulating layers, like amorphous boron nitride, are added during the process of making these ultra-thin materials, which are used to build next-generation electronic devices. (Image: J.A. Robinson Research Group/Penn State)