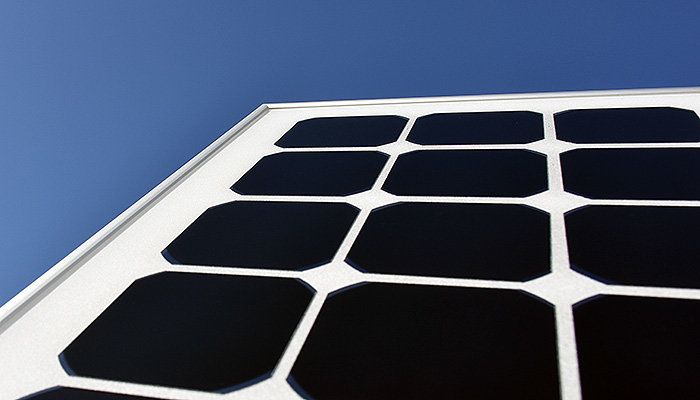

A 2011 invention made by Aalto University’s researchers has proceeded from concept to reality. Just a few years ago the researchers obtained the record efficiency of 22% in the lab for nanostructured solar cells using atomic layer deposition, and now with the help of industrial partners and joint European collaboration, the first prototype modules have been manufactured on an industrial production line.

“Our timing could not have been better” prof. Hele Savin, who led the research, was pleased to tell. Indeed, 2018 is commonly called the “Year of Black Silicon” due to its rapid expansion in the photovoltaic (PV) industry. It has enabled the use of diamond-wire sawing in multicrystalline silicon, which reduces costs and environmental impact. However, there is still plenty of room for improvement as the current black silicon used in industry consists of shallow nanostructures that leads to sub-optimal optical properties and requires a separate antireflection coating.

Aalto’s approach consists of using deep needle-like nanostructures to make an optically perfect surface that eliminates the need for the antireflection coatings. Their industrial production, however, was not an easy task. “We were worried that such a fragile structure would not survive the multi-step mass production, because of rough handling by robots or module lamination.”

Comments are closed.