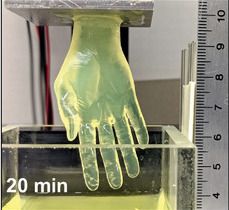

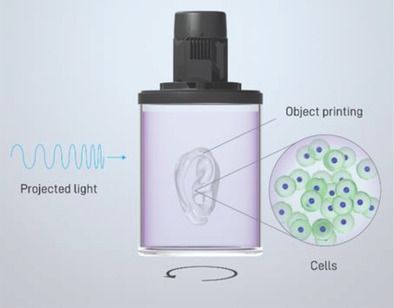

Bioprinting in seconds.

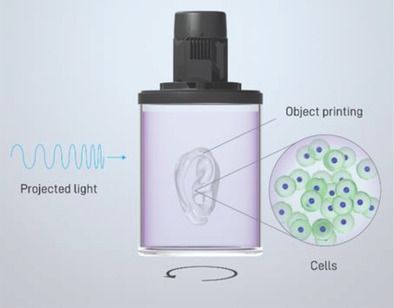

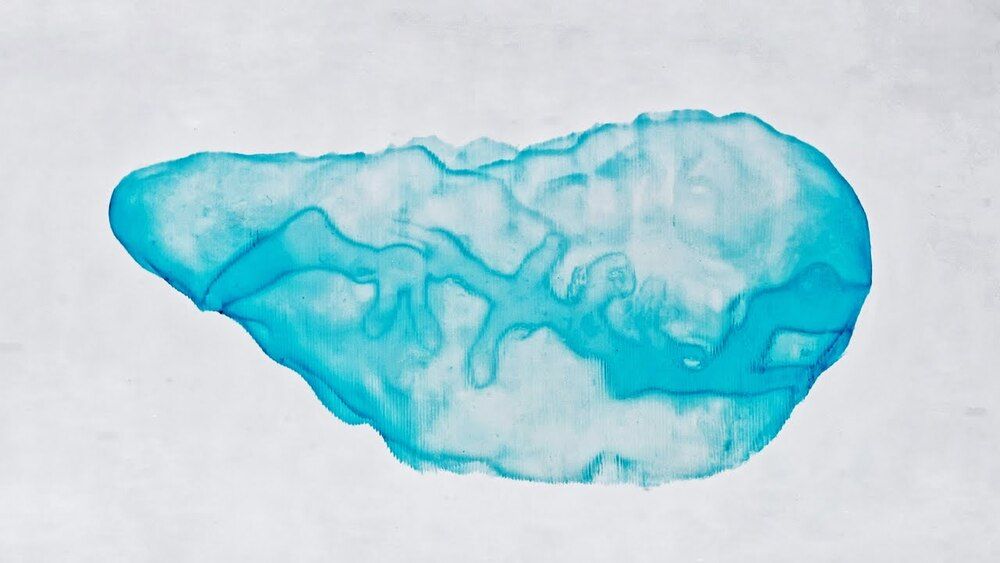

Biofabrication technologies, including stereolithography and extrusion-based printing, are revolutionizing the creation of complex engineered tissues. The current paradigm in bioprinting relies on the additive layer-by-layer deposition and assembly of repetitive building blocks, typically cell-laden hydrogel fibers or voxels, single cells, or cellular aggregates. The scalability of these additive manufacturing technologies is limited by their printing velocity, as lengthy biofabrication processes impair cell functionality. Overcoming such limitations, the volumetric bioprinting of clinically relevant sized, anatomically shaped constructs, in a time frame ranging from seconds to tens of seconds is described. An optical-tomography-inspired printing approach, based on visible light projection, is developed to generate cell-laden tissue constructs with high viability (85%) from gelatin-based photoresponsive hydrogels. Free-form architectures, difficult to reproduce with conventional printing, are obtained, including anatomically correct trabecular bone models with embedded angiogenic sprouts and meniscal grafts. The latter undergoes maturation in vitro as the bioprinted chondroprogenitor cells synthesize neo-fibrocartilage matrix. Moreover, free-floating structures are generated, as demonstrated by printing functional hydrogel-based ball-and-cage fluidic valves. Volumetric bioprinting permits the creation of geometrically complex, centimeter-scale constructs at an unprecedented printing velocity, opening new avenues for upscaling the production of hydrogel-based constructs and for their application in tissue engineering, regenerative medicine, and soft robotics.