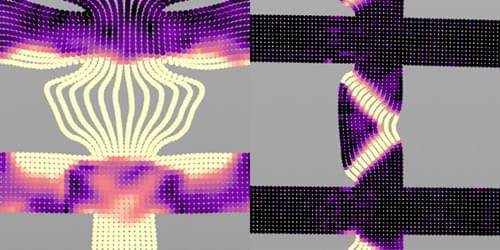

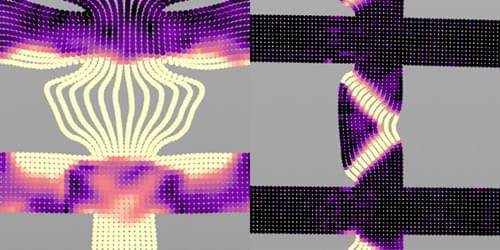

A model attributes the propagating bands that appear in a compressed porous medium to structural changes alone.

Porous media such as snow, sand, cereals—even bones—develop strikingly similar banded patterns when they’re squeezed. Those bands form when localized deformation zones propagate throughout the material. Understanding what triggers the universal and “material-agnostic” emergence of the bands is a common goal in disciplines including avalanche research, petroleum extraction, structural engineering, geophysics, and agriculture. Now, describing the phenomenon using a model based entirely on a collapsing-pore mechanism, Lars Blatny and his colleagues at the Swiss Federal Institute of Technology, Lausanne, and the University of Sydney, Australia, identify a common origin for these patterns. The result could lead to comprehensive continuum-mechanics models of porous media.

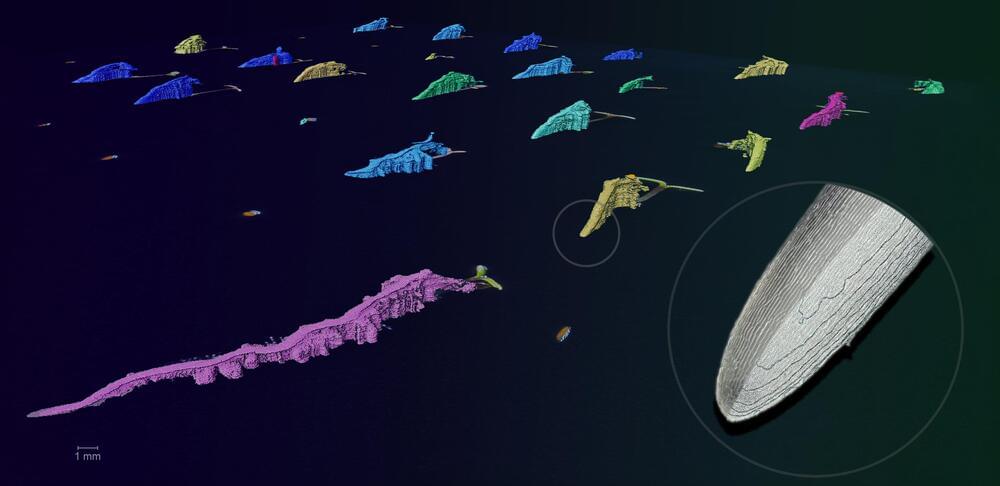

Blatny and his colleagues simulated a vertical 2D slice of an elastoplastic structure that was squeezed from above and below. The structure was perforated with regularly spaced square holes that composed 25% to 75% of its total area. By varying the solid area fraction and the structure’s elasticity and yield strength, the researchers examined how different porous structures deform when compressed at a constant speed. They identified six classes of compaction patterns and found that they could describe these classes entirely by two numbers that characterize the material’s properties and the speed at which the structure was compressed.