Oct 26, 2022

Scientists discover material that can be made like a plastic but conducts like a metal

Posted by Jose Ruben Rodriguez Fuentes in categories: materials, transportation

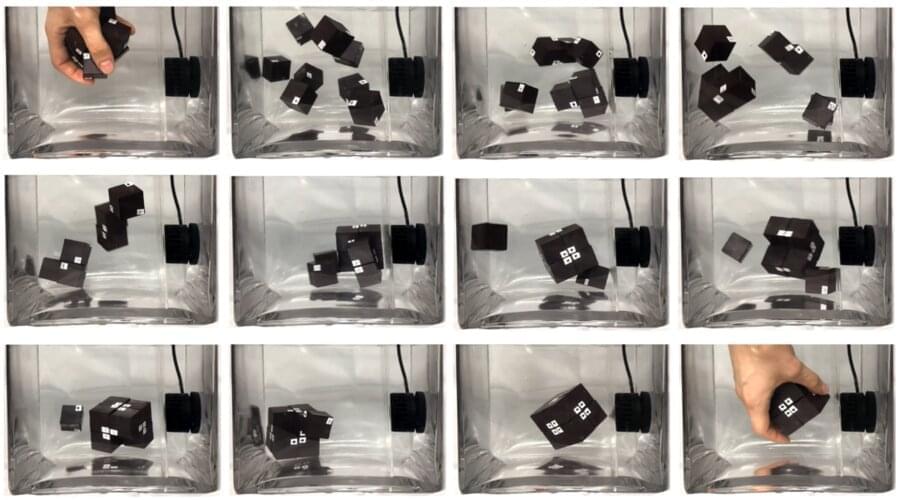

Scientists with the University of Chicago have discovered a way to create a material that can be made like a plastic, but conducts electricity more like a metal.

The research, published Oct. 26 in Nature, shows how to make a kind of material in which the molecular fragments are jumbled and disordered, but can still conduct electricity extremely well.

This goes against all of the rules we know about for conductivity—to a scientist, it’s kind of like seeing a car driving on water and still going 70 mph. But the finding could also be extraordinarily useful; if you want to invent something revolutionary, the process often first starts with discovering a completely new material.